In the context of seeking safe and eco-friendly additives, soy lecithin and sunflower lecithin have emerged as prominent natural emulsifiers, extensively utilized across the food, cosmetics and animal nutrition sectors. This analysis delineates their origins, extraction methodologies, compositional distinctions and functional applications, providing guidance to help you select the most suitable product.

Overview of Lecithin

1. What is Lecithin? Origins and fundamental properties

Lecithin is a group of naturally occurring phospholipids present in biological cells, particularly abundant in soybeans, sunflower seeds, egg yolks and certain other oilseeds. Possessing strong emulsifying capabilities, lecithin facilitates the blending of immiscible components such as oil and water, making it widely utilized across the food, pharmaceutical, cosmetic and animal feed industries.

What sets lecithin apart is its molecular structure, comprising a hydrophilic “polar head”' and a hydrophobic “non polar - tail”, enabling it to function as a bridge between two distinct liquid phases. This characteristic renders lecithin a natural, safe and environmentally friendly emulsifier, serving as a sustainable alternative to synthetic agents in various industrial applications.

2. Distinguishing Natural Lecithin from Synthetic Lecithin

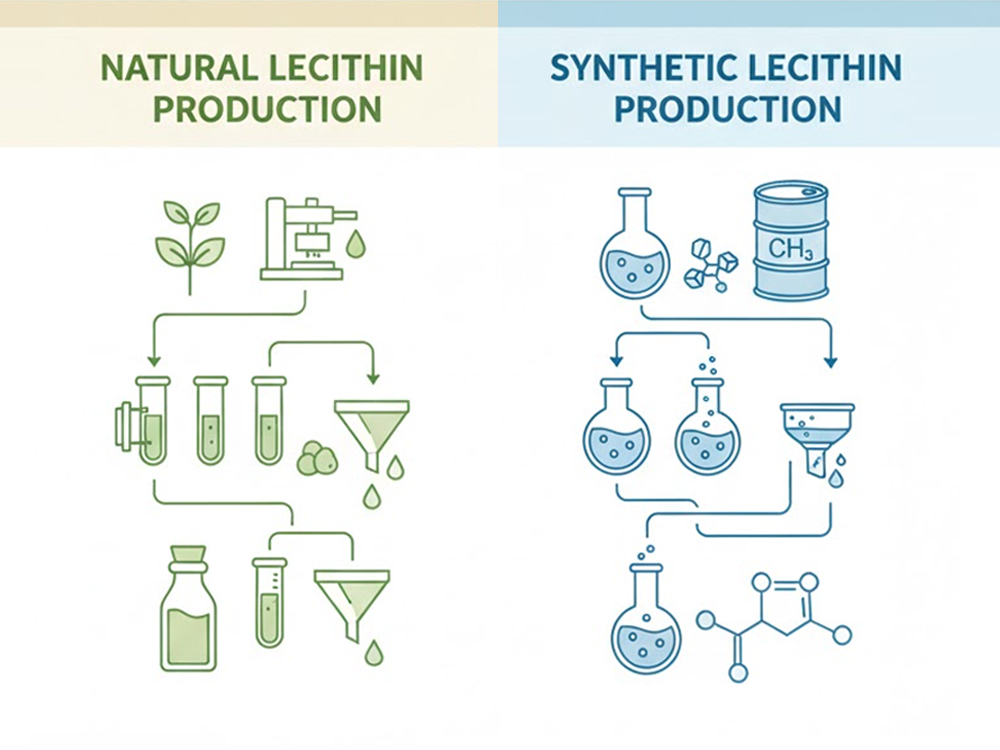

Natural lecithin is typically extracted from plant-based sources such as soybeans or sunflower seeds through pressing, oil separation and refining processes without the use of harmful chemical solvents. This method preserves the phospholipid content, choline and essential fatty acids, offering health benefits and ensuring biodegradability.

In contrast, synthetic lecithin is produced via chemical reactions from artificial compounds. Although it is more cost-effective and exhibits consistent quality, synthetic lecithin lacks natural properties, environmental compatibility and may contain impurities. Consequently, enterprises increasingly prioritize natural lecithin such as soy and sunflower lecithin in their production processes.

Exploring Soy Lecithin

1. Manufacturing process of Soy Lecithin

Soy lecithin is extracted during the refining of soybean oil. Specifically, when crude oil is separated from the beans, the “gum” - a colloidal layer rich in phospholipids is isolated, then dried and refined to obtain pure soy lecithin.

The production process typically involves the following steps:

-

Separation of crude soybean oil

-

Hydration to isolate the phospholipid fraction

-

Centrifugation to remove water

-

Vacuum drying and fine filtration to produce the final product

The resulting soy lecithin is available in liquid or powder form with a pale yellow color, mild odor and excellent solubility in oils.

2. Composition and applications of Soy Lecithin

Soy lecithin contains key phospholipids such as phosphatidylcholine, phosphatidylethanolamine and phosphatidylinositol - compounds that support cellular function, enhance memory and aid lipid digestion.

In industrial applications, soy lecithin is widely utilized:

-

Food industry: Improves cake softness, smooths chocolate, homogenizes milk and extends shelf life.

-

Animal feed: Enhances survival rates, nutrient absorption and optimizes lipid metabolism in fish, shrimp and poultry.

-

Cosmetics and pharmaceuticals: Serves as a natural emulsifier and moisturizer.

Exploring Sunflower Lecithin

1. Composition and manufacturing process of Sunflower Lecithin

Similar to soy lecithin, sunflower lecithin is extracted from sunflower seeds - a source naturally rich in phospholipids and non-GMO, aligning with the growing demand for sustainable and eco-friendly products.

The production process is entirely solvent-free, relying primarily on mechanical pressing, filtration and drying, preserving the full nutritional value. The final product is available in liquid, powder or fine granule form, depending on the intended use.

In terms of composition, sunflower lecithin contains:

-

Phosphatidylcholine (higher content than in soy lecithin)

-

Phosphatidylinositol and linoleic acid, providing antioxidant properties and cellular protection

-

Natural choline, supporting liver function and neurological health

2. Applications of Sunflower Lecithin in food and health sector

Sunflower lecithin serves as an optimal alternative to soy lecithin across various industries, particularly for individuals with soy allergies or those seeking vegan, non-GMO products.

Common applications include:

-

Food industry: Enhances texture, stabilizes moisture, facilitates the blending of butter, chocolate and dairy products.

-

Functional foods: Provides choline supplementation, supporting memory enhancement, lipid metabolism and cholesterol reduction.

-

Cosmetics: Promotes skin hydration, cell regeneration, improves product smoothness in skincare formulations.

Comparing Soy Lecithin and Sunflower Lecithin

|

Criteria |

Soy Lecithin |

Sunflower Lecithin |

|

Origin |

From soybean seeds |

From sunflower seeds |

|

Manufacturing process |

Mechanical pressing or enzyme-assisted extraction, without the use of chemical solvents |

Mechanical pressing, solvent-free |

|

Key components |

Phosphatidylcholine, phosphatidylethanolamine, unsaturated fatty acids |

Phosphatidylcholine, phosphatidylinositol, acid linoleic |

|

Advantages |

Cost-effective, abundant supply, safe and environmentally friendly |

Pure, mild, suitable for premium products |

|

Disadvantages |

Can be mistaken for GMO unless properly certified |

Higher cost, limited production volume |

|

Applications |

Food, animal feed, cosmetics, pharmaceuticals |

Food, functional foods, high-end organic cosmetics |

Modern industry trends in Lecithin production and utilization

Amid the global manufacturing shift toward sustainability and eco-friendliness, soy and sunflower lecithin are increasingly recognized as new-generation emulsifiers that combine technical efficiency with environmental friendliness.

Enterprises are focusing on:

-

Optimizing lecithin production through biotechnological processes to enhance purity.

-

Developing new-generation natural and synthetic lecithins with improved viscosity control and stability.

-

Incorporating lecithin into premium products such as functional foods, sports nutrition and organic cosmetics.

Lecithin is not merely an emulsifier; it embodies the trend toward green, clean and safe solutions, contributing to modern industries that prioritize sustainability and human health.

Lecithin solutions from Masi

Masi provides high-quality liquid lecithin to animal feed manufacturers nationwide. Beyond supplying raw materials, Masi serves as a trusted technical partner, assisting businesses in optimizing emulsification formulas, enhancing lipid digestibility, and ensuring consistent product quality. The lecithin source is strictly controlled from the outset, meeting safety standards, fully traceable, and COAs are available upon request.

With extensive experience and expertise in animal nutrition, Masi partners with feed mills to improve efficiency, optimize costs and support sustainable development. Contact Masi today for detailed consultation on lecithin products and tailored application solutions for your specific animal feed lines.

--------------------------------------

Contact information:

Masi

- Office: 7th Floor, Giga Mall, 240–242 Pham Van Dong, Hiep Binh Ward, Ho Chi Minh City, Vietnam

- Production Facility 1: Lot C11, Fish Sauce Processing Zone, Phu Thuy Ward, Lam Dong Province, Vietnam

- Production Facility 2: Hoi Hamlet, Kim Son Commune, Dong Thap Province, Vietnam

Email: Cs@masi.vn

Call center: 0909 411 885 - 0911 401 955 - 0979 045 766

Facebook: https://www.facebook.com/masi.fishmeal

LinkedIn: https://www.linkedin.com/company/masifishmeal/