Kim Long fish meal is produced by a closed manufacturing process, meeting the international quality standards GMP+, certificate regulation, certificate standards, and standard conformity certificate (TCCS 01:2022/MS). The production process is strictly implemented from raw materials to finished products, ensuring that the technical standards are met according to the requirements of Customers. Kim Long fish meal accompanies many businesses in the animal feed industry, and it is considered a vital link for ensuring essential nutrients, enhancing absorption, and improving animal health and development.

Vision - Mision

Vision - Mision

Vision

Becoming a leading fish meal supplier in providing ingredients for the animal feed industry.

Mision

We maintain a sustainable business culture, focus on enhancing intensive training and moral qualities. We also produce superior-quality products with optimum nutrition to foster the growth and development of livestock, fish, and other aquatic species. Moreover, We promote the sustainable development and prosperity of the animal feed industry and Vietnam’s agriculture.

Product quality

Product quality

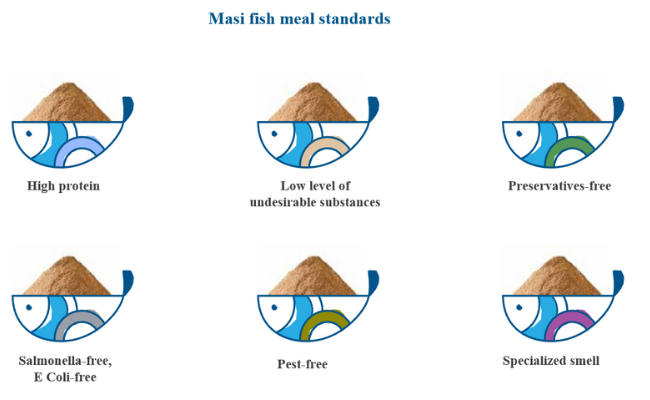

With the criteria “Quality is the lodestar,” Kim Long is proud to be your trustworthy and long-term strategic partner of many valued Customers. Moreover, We enhance our quality products and gain a competitive edge in the market by maintaining a closed manufacturing process and strict inspection of raw materials.

Kim Long fish meal ensures the percentage of protein, the lowest level of undesirable substances, and antibiotic-free criteria in a strict quality control process. These elements are considered to be the decisive factors that help create nutritional values and promote the outstanding development of animals.

Kim Long fish meal has been certified by the international GMP+ Feed Certification Scheme for safe animal feed, the certificate regulation, the certificate standards, and the Standard conformity certificate TCCS (TCCS 01:2022/MS).

Manufacturing factory

Manufacturing factory

The manufacturing factory is located in the fish sauce processing zone of Phu Hai Ward - one of the largest manufacturing factories in Phan Thiet City. It has a separate functional area, including a truck weigh station, raw material area, processing zone, ingredients selling zone, and showroom. The manufacturing is also well equipped with modern machines provided by reputable entities internationally, such as conveyors, steamers, flour mills, sieve screening, and centrifuges

Location and geographical features

Binh Thuan province is endowed by nature with 192 kilometers long and four surrounding ports: Phan Thiet, Phu Hai, Lagi, and Mui Ne. Therefore, Kim Long has more opportunities to select and purchase safe, fresh fish sources to save cost and transportation time, guaranteeing the quality of raw material.

Besides the many advantages of large marine ports,Kim Long's head office is located in Ho Chi Minh city - one of Vietnam's economic and financial centers that enhance trade opportunities, expand potential markets, and export products to regional countries.

Standard systems

- The wastewater treatment system meets the standards of QCVN 11:MT/2015/BTNMT (National technical regulation on seafood processing wastewater).

- The exhaust treatment system and steam boiler meet the standards of the HCMC Science of Occupational Safety and Health Institute.

- The steam boiler and fish drying system meet the standards of QCVN 19:2009/BTNMT.

Machineries

Vehicles