Sources Of Raw Material For Fish Meal Production

Fish meal is one of the raw materials for producing animal feed with high protein content, fully supplementing essential nutrients for the growth and development of livestock. To understand more about fish meal production, let's read the article below with Masi.

Sources of raw material for fish meal production

Fish meal was made from low-value fish. The primary source of raw materials in fishmeal production is saltwater fish and pangasius (freshwater fish) along with fish by-products. It is not only helps promote the development of the animal feed industry, but also increase the value of low-value fish, contributing to strengthening the development economy. After processing, fishmeal products are obtained, used as raw materials for the production of animal feed, poultry, seafood and pet food.

Masi uses 100% fresh sea fish ingredients, such as anchovies, bulls, catfish, herring... with modern - closed production lines, ensuring the best product quality when reaching our customers. row.

>> See more: The important role of fishmeal in Animal feed production

Sources of raw material for fish meal production

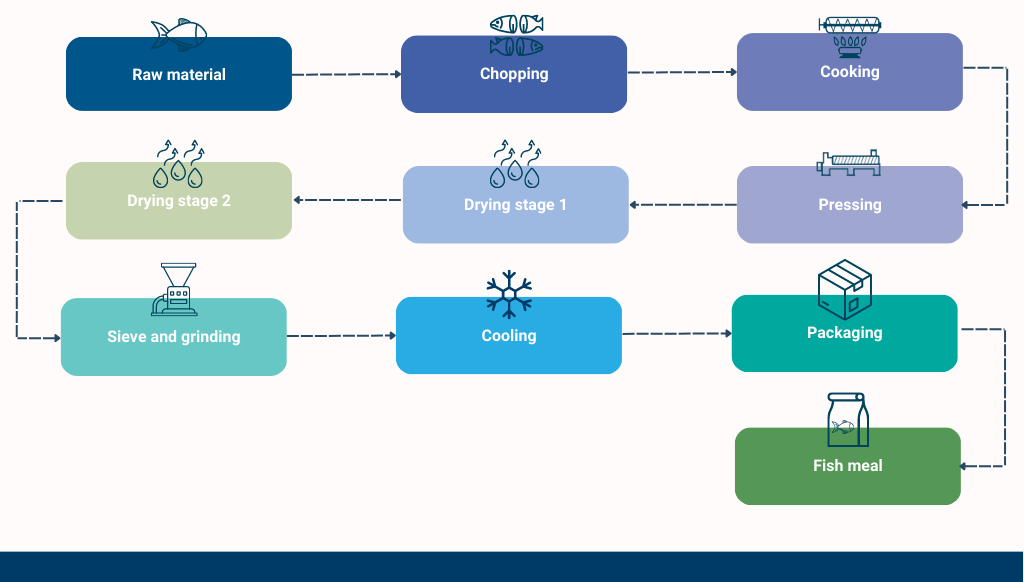

Fish-meal production

Step 1: Raw fish

Fresh fish will be transported to the factory by specialized transport vehicles, and the fish will be classified according to each criterion to ensure the finished product's quality.

Step 2: Cutting

After being sorted and processed, fish will be taken to the feeder with a large capacity. Then, they are transferred to the cutter to grind, ensuring optimal cooking efficiency.

Step 3: Cooking

The ingredients are cooked at a high temperature to kill bacteria and easily separate the fat and moisture from the solids.

Step 4: Pressing

The press will divide the ingredients into two parts: liquid and solid. The solid will be transported to the dryer for the next step.

Step 5: Drying

After drying process, the solid will be cooled.

Step 6: Cooling

Through the cooling system, the vortex air and circulating water cool down at a temperature of 35 to 38 degrees to preserve product quality.

Step 7: Grinding

The solid will be ground to obtain fish meal.

Step 8: Packaging

Fish meal will be packed according to the volume requirements of the Customer.

Step 9: Transporting

From the fish meal factory the meal is transported to all domestic and international customers.

Fish meal production at Masi

Intructions

-

Cooked feed: Powdery food can be cooked in the form of porridge. Cooking food helps fish digest and absorb nutrients better in order to save food and improving economic efficiency.

-

Fermented feed: Food (powder form) mixed sufficiently moist (about 40% moisture) with yeast, incubated for 12 to 24 hours depending on the temperature. Fermented feed has aroma, high nutritional value, easy to digest. However, it is hard to preserve for a long time. It is possible to mix food with vitamins or drugs to prevent and treat fish diseases. With cooked foods, mix vitamins only after they are cooked and mix when the food has cooled down (>400C) to prevent vitamins from breaking down.

The information above will help customers understand the raw materials for fishmeal production and production processes. As one of the leading fishmeal distributors in Vietnam, Masi always wants to bring customers quality fishmeal products at reasonable prices through fresh ingredients, modern equipment and an automatic production line.

---------------------------------------

Contact information:

Masi

-

H.O: 7F, Gigamall Trade Center, 240-242 Pham Van Dong St., Hiep Binh Chanh W., Thu Duc City, HCMC.

-

Manufactured by: Kim Long fish meal factory - Lot C11, Fish Sauce Processing Zone, Phu Hai W., Phan Thiet City, Binh Thuan Province.

Email: Cs@masi.vn

Call center: 0909 411 885 - 0911 401 955 - 0979 045 766

Facebook: https://www.facebook.com/masi.fishmeal

LinkedIn: https://www.linkedin.com/company/masifishmeal/

Website: https://masi.vn/