Masi Conquers the International Market

As global trade becomes increasingly standardized, major markets are tightening requirements for exporting enterprises, not only in terms of product quality but also supply capability and raw material traceability. As a result, market expansion today is no longer driven solely by output or pricing, but requires businesses to establish a sustainable operational foundation and a stable, long-term supply chain.

Masi is an ecosystem specializing in supplying raw materials to domestic and international animal feed producers, with two core product groups: agricultural-based ingredients and marine-based ingredients. From its early development strategy, the company has chosen to control supply at the production stage - considered the foundation for ensuring consistent quality, operational stability and long-term fulfillment capacity for partners.

Kim Long factory covers an area of over 10,000 m²

Kim Long factory covers an area of over 10,000 m²

Currently, the company owns and operates three manufacturing facilities whose outputs complement one another. Among them, Kim Long and Kim Dao factories are located in Phan Thiet, close to seaports, creating favorable conditions for sourcing fresh marine fish while optimizing production, logistics and delivery. The integration of Kim Dao into the ecosystem has enabled Masi to form a synchronized production cluster, enhancing its capacity to supply high-specification products such as fishmeal and squid meal.

Kim Dao factory covers an area of over 10,000 m²

Kim Dao factory covers an area of over 10,000 m²

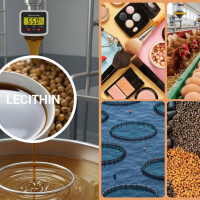

In the agricultural ingredients segment, Tien Phat Factory (Dong Thap) specializes in rice bran production for the animal feed industry, contributing to the completion of Masi’s supply chain ecosystem. In addition to core products such as fishmeal, fish oil, fish solubles and rice bran, the company also supplies a wide range of materials including broken rice, rice husk, cassava chips, cassava pulp, corn, lecithin, rice bran oil, soybean meal and DDGs - forming a closed-loop raw material ecosystem.

Tien Phat Factory (Dong Thap)

Tien Phat Factory (Dong Thap)

Alongside investments in production capacity, Masi has developed a raw material management and control system aligned with international standards. The company participates in the Fishery Improvement Project (FIP) under the MarinTrust IP framework, aimed at strengthening marine resource management while aligning with environmental impact mitigation requirements.

In daily operations, the group has invested comprehensively in factories, production lines, warehouses and laboratories to ensure quality control at every stage. Nutritional parameters, moisture levels, impurities and storage conditions are regularly monitored. At the same time, the company applies and maintains certifications including GMP+, ISO 22000:2018 and HACCP…

With a standardized production and management system in place, Masi currently exports consistently to markets such as Japan, Bangladesh and Taiwan.

China is regarded as a market with particularly stringent requirements for animal feed raw material exporters, especially marine-based products such as fishmeal. Beyond product quality, the market evaluates enterprises on management capability, production systems, risk control and raw material traceability.

Masi is among a limited number of enterprises authorized to export fishmeal to China and has been granted an official exporter registration code (GACC). Meeting these requirements provides a foundation for official exports while reflecting the level of standardization across the company’s production and governance systems.

Mr. Son Quang, Group Marketing Director, stated that participation in the MarinTrust project and the completion of procedures to export fishmeal to China demonstrate the company’s commitment to promoting the sustainable development of Vietnam’s fisheries, while reaffirming its responsibility to society and the community. This also serves as evidence that Masi’s products meet international standards.

Masi is a member of the Care Solutions Group, inheriting its governance expertise, standardized ERP systems, 24/7 customer services, in-house logistics and multilingual workforce. This integrated approach to management and operations enables Masi to maintain consistency across its production and business activities, while providing partners with a reliable foundation for long-term, sustainable cooperation.